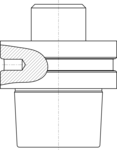

Certainly not as you know that axle and bearing damage as well as worst driving comfort would be the result!

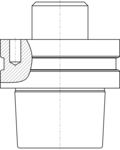

In case of unbalanced rotors (for example, tools), it behaves similarly "bumpy".

On the other hand, well-balanced rotors ensure longevity and perfect operating conditions (for example chatter-free running, longer service life, better surfaces)

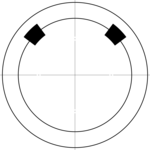

Before balancing, check whether and where unbalance is present.

If there is no unbalance, you do not have to balance it either.

However, you should check in any case, because one rotor with too much unbalance in your machine spindle can already be one too much!